Fa'ailoa:

E taua tele le faʻapipiʻiina o le PCB lelei i le faʻapotopotoga manuia ma le faʻaogaina o eletise eletise. Faʻamauina lelei e faʻamautinoa ai se fesoʻotaʻiga eletise faʻalagolago, lea e aʻafia ai le faʻatinoga o le taamilosaga atoa.Le a su'esu'eina e lenei ta'iala ta'iala le 'ese'ese auala, ituaiga, ma faiga fa'aa'afia ile fa'amauina o le PCB. E ala i le malamalama i nei vaega, e mafai ona e faia faʻaiuga faʻamaonia pe a filifilia faiga faʻapipiʻi talafeagai ma meafaigaluega.

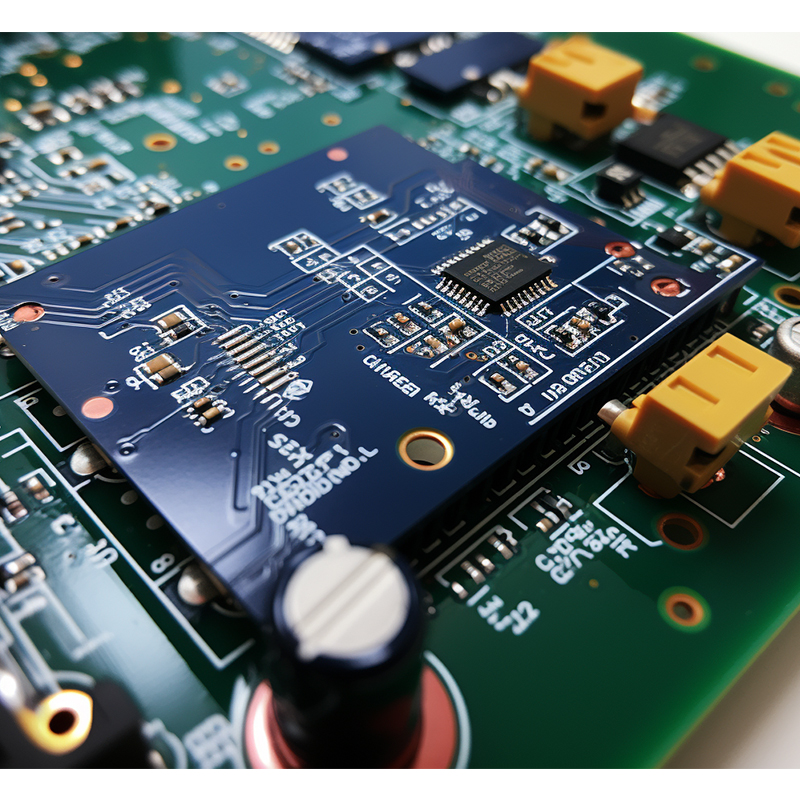

Va'aiga fa'apipi'i PCB:

PCB uelo, e lauiloa foi o le soldering, e aofia ai le faia o sootaga eletise faatuatuaina i le va o vaega faaeletonika ma laupapa matagaluega. E faia se sao taua i le faʻamautinoaina o le gaioiga masani o le matagaluega atoa. auala soldering eseese o loo faaaogaina i le faapotopotoga PCB, taitasi ma ona lava faamanuiaga ma iloiloga.

Aoao e uiga iPCB sotini tekinolosi:

A. faiga uelo PCB:

Ina ia ausia se faʻailoga manuia, e taua le mulimulitaʻi i se faʻasologa auiliili. O lenei vaega o le a otooto atu ai le laasaga-i-laasaga faagasologa o solder PCB. O le a aofia ai foi le saunia o vaega PCB mo soldering ma otooto meafaigaluega talafeagai ma meafaigaluega.

B. masani PCB solder metotia:

Fa'amauina i le pu:

O le fa'amauina o pu ose auala fa'aoga lautele lea e aofia ai le fa'apipi'iina o vaega e ala i pu na mua'i viliina i totonu o se laupapa ta'amilosaga. O lenei vaega o le a tuʻuina atu se faʻamatalaga o le auala faʻapipiʻi i totonu o le pu, talanoaina ona lelei ma le le lelei, ma faʻamaonia faiga sili ona lelei ma faʻaoga.

Fa'amauina fa'amau i luga ole laiga:

Fa'apipi'i fa'amau i luga, e ta'ua fo'i o le fa'apipi'iina o masini fa'apipi'i (SMT), e masani ona fa'aaogaina e fa'aitiitiina ai vaega fa'aeletoroni. O lenei vaega o le a tuʻuina atu se faʻamatalaga lautele o le SMT soldering technology, ona faʻamanuiaga, tapulaʻa, ma iloiloga autu mo le faʻatinoina manuia.

Uu lelei le pitch:

O le fa'apipi'iina o vaega fa'apito lelei e mafai ona tu'u mai ai ni lu'itau fa'apitoa ona o le vavalalata o pine. O lenei vaega o lo'o su'esu'eina fa'afitauli e feso'ota'i ma le so'ina o vaega fa'alelei ma tu'uina atu fautuaga ma puipuiga mo le ausiaina sa'o o so'oga so'o. E le gata i lea, o mea faigaluega ma mea faigaluega e fesoasoani i le ausiaina o le uelo sa'o lelei o le a talanoaina.

Ufiufiina o le laupapa malo-felagolagomai:

uelo fa'alelei ma'a'a e fa'atatau i le fa'agasologa o le fa'apipi'iina o vaega i luga o se laupapa va'aiga fe'avea'i fa'atasi ma se vaega mautu. O lenei vaega o le a faʻalauiloaina le tekonolosi i tua o le solder maʻaʻa-fele, talanoa i luʻitau o loʻo aʻafia ai, ma tuʻuina atu fofo e faʻamautinoa ai le maualuga o solder solder i totonu o faʻapotopotoga PCB faʻamalosi.

HDI PCB sosolo:

High-density interconnect (HDI) PCBs faʻaalia mamanu lavelave ma maualuga vaega density. Soldering HDI PCB e manaʻomia le poto faʻapitoa. O lenei vaega e suʻesuʻeina le lavelave o solder HDI PCBs, faʻamaonia le tomai manaʻomia, ma talanoaina le lelei ma iloiloga o HDI PCB soldering.

Fautuaga mo fa'amauina PCB manuia:

A. Sauniuniga ma Fuafuaga:

Manuia PCB soldering e amata i le saunia lelei ma fuafuaga. O lenei vaega o loʻo faʻatalanoaina le taua o le PCB faʻatulagaina ma le tuʻuina atu o vaega e faʻafaigofie ai le faiga faʻapipiʻi. O le a faʻamamafaina foi le manaʻoga e filifili le auala saʻo solder e faʻavae i luga o le mamanu PCB ma le taua o le faʻaoga saʻo o le solder paste.

B. Fa'agasologa uelo ma filifiliga meafaigaluega:

Filifilia sa'o meafaigaluega uelo ma meafaigaluega e taua tele i le ausiaina o taunuuga uelo manuia. O lenei vaega o le a taʻitaʻia oe i le fuafuaina o meafaigaluega talafeagai ma meafaigaluega mo se galuega patino. O le a fa'atalanoaina fo'i mea e tatau ona mafaufau i ai pe a filifilia mea uelo ma fa'amamafa le taua o le fa'aogaina o tala'aga o le vevela talafeagai.

C. Puleaina lelei ma Asiasiga:

O le faʻatinoina o faiga faʻatonutonu lelei ma le faʻatinoina o asiasiga i le faagasologa o le uelo e taua tele i le faʻamautinoaina o solder faʻalagolago. O lenei vaega o loʻo faʻatalanoaina auala faʻapipiʻi vaʻaia vaʻaia, faʻapea foʻi ma auala suʻesuʻe ma meafaigaluega e mafai ona faʻaaogaina e iloilo ai le lelei o le uelo.

Fa'ai'uga:

I se aotelega, o lenei taiala atoatoa e aofia ai le taua o le lelei PCB soldering ma le aafiaga o soldering sa'o i luga o galuega tauave matagaluega. E ala i le filifilia o le faiga sa'o solder ma metotia, e mafai ona e ausia tulaga maualuga solder sooga. Sauniuniga tatau, filifiliga meafaigaluega ma le faaeteete, ma le pulea lelei atoatoa o ki ia manuia PCB soldering. O le teu faafaigaluegaina o meafaigaluega soldering maualuga ma mulimuli i faiga sili ona lelei o le a maua ai taunuuga sili i PCB faapotopotoga.

Taimi meli: Nov-07-2023

Tua